Stainless Steel Round Pipe / Tube: Round tube:OD 9.5-219mmWall thickness: 0.4~2.0 mmMaterial: 201 series,304 seriesSur face finish:Mirror 600#, satin/hairline.The products have beautiful appearance and high quality ,then widely used in architectural decoration, furniture, etc Features: Stainless steel square Pipe/Tube: Square tube:size from 12*12 mm To 101*101 mm.Wall thickness: 0.4~2.0 mmMaterial: 201 series,304 seriesSur face finishRead More

Blog

Hand and Power Tools & Pressure Washer in Pakistan

POWER TOOLS Power tools are a common part of our everyday lives and are present in nearly every industry. These tools help us to easily perform tasks that otherwise would be difficult. AVAILABLE PRODUCTS Available Brands: DEWALT, MAKITA, HYUNDAI, BLACK AND DECKER, MAKUTE, SENCAN, CROWN, AND BOKY. OTHER INDUSTRIAL PRODUCTS DRILL PRESS The drill pressRead More

GASKET SHEET & PTFE PRODUCTS

GASKET SHEET / JOINTING SHEET Jointing Materials are sealants used for applications across chemical plants, refineries, and thermal applications. Jointing Sheets are cut out in various sizes to form a compressible leak-proof seal between two surfaces or components. These Gasket Sheets are flexible and robust to be used in applications that involve acids, high temperature,Read More

PRESSURE MEASURING INSTRUMENTS

Instruments used to measure and display pressure mechanically are called pressure gauges, vacuum gauges or compound gauges (vacuum & pressure). The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge. This pressure measurement device measures the pressure in gases and liquids. There isRead More

Digital Weight Scale or Weight Machine

What is a Digital Weight Scale? A Digital Weight Scale is an electronic device used for measuring the weight or mass of an object or person. It utilizes digital sensors to convert the mechanical force of an object’s weight into a numerical reading, which is displayed on a digital screen. These scales are known forRead More

AIR COMPRESSOR HOSE

Air Compressor Hose can be used in a variety of settings, including industrial, commercial, and residential

BRAIDED HOSE

We provide a variety of PVC Braided Hose that is specifically built for low pressure applications and is available at extremely reasonable pricing. Special Features Basically, this hose is made of high-quality PVC that has been braided into a pattern to assure its relevance. Oil, water, and acids can all be used with these. 1/2′′,Read More

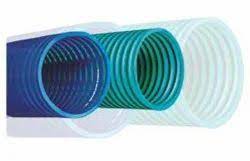

PVC SUCTION VINYL HOSE

Suction and discharge hoses (also known as suction and delivery hoses) are one of the largest hoses we make in terms of diameter, and they’re normally composed of flexible PVC with a helix. Depending on the use and endurance required, the flexibility of these hoses can range from rigid to ultra flexible. These hoses workRead More

CNG HOSE / LGP HOSE

ELECTRICALLY CONDUCTIVE VERY FLEXIBLE, EASY TO INSTALL WITH FASTER ROUTING AND SIMPLE MAINTENANCE ROBUST DESIGN, RESISTANT TO STRESS, CORROSION, AND ENVIRONMENTAL EFFECTS ISO 15500-17, MSHA STANDARDS EXCEED NFPA 52, ANSI/CSA NGV 4.2-2014 AND CSA 12.52-2014 ELECTRICALLY CONDUCT. Construction: External pin-pricked anti-abrasion RED waterproof polyurethane covering, inner core in electrically conductive polyamide, reinforcement in high toughnessRead More

Car Washer/Service pipe

Umar Farooq Belting: Unleashing Efficiency with Car Washer/Service Pipes Introducing Umar Farooq Belting’s cutting-edge Car Washer/Service Pipes – the epitome of precision and durability in automotive maintenance. Our pipes are meticulously crafted to meet the demanding needs of car washing and servicing applications, ensuring efficient water delivery and lasting performance. Key Features of Umar FarooqRead More