Some conveyor belting is manufactured with one ply of fabric. This fabric layer can be coated with rubber, polymer or elastomer. Yet, most conveyor belting is manufactured using two or more plies of fabric that are adhered to each other by using inner layers of rubber, polymer or elastomer.

In addition, there can be top or bottom surface covers of rubber, polymer or elastomer.

While ply adhesion is defined as the force required to separate two adjoining plies, the reality is that ply adhesion is the force required to pull apart the adhesion that joins the plies. This is measured in pounds per inch or newtons per millimeter.

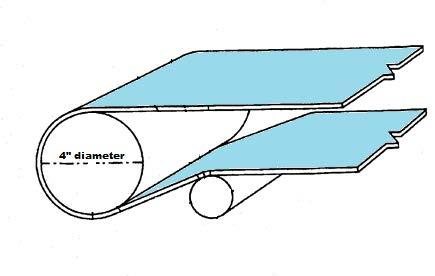

Conveyor belts operate on equipment that requires flexing over pulleys on the conveyor. This repeated flexing action will stress the ply adhesion of conveyor belts. As a result, it is important for the belt to have adequate ply adhesion to resist ply separation.

(the bottom ply bends over a smaller radius)

The test for ply adhesion is a “pull test” and can be accomplished with a simple clamping device and a fish scale. The test for ply adhesion is usually done on 1” wide x 8” long samples. Multiple samples of the product should be tested and tests should be conducted on the samples from both directions in order to achieve statistical measurements. Belt manufacturing processes can produce different measurements depending on direction of pull

In general terms, ply adhesion of less than 13-lbs per inch of width is considered unacceptably low. Ply adhesion of more than 50-lbs per inch of width is considered very high and can create challenges in belt fabrications where the plies need to be separated manually.

Synthetic fabrics (i.e. polyester, nylon) are often treated with RFL (resorcinol formaldehyde latex) during manufacturing in order to increase the ply adhesion because, without this treatment, the synthetic fabrics are too smooth and too resistant to effectively absorb the polymer, elastomer or rubber in a manner that achieves acceptable ply adhesion. Cotton, by contrast, is coarser and more absorbent, therefore not requiring RFL treatment to achieve acceptable ply adhesion.

Examples of Minimum Adhesion Standards in Sparks’ Belts

- 14-lbs/inch Untreated Polyester- Poly Flake, Sno Cone, TevTex 22M & 32M

- 18-lbs/inch Untreated Cotton/Nylon – HSW, 144 TevTex

- 18-lbs/inch Untreated Cotton Polyester – 28 NOS, Nytop

- 22-lbs/inch RFL Treated Polyester Econo- Rough Black, Food King 3W

- RFL Treated Polyester/Nylon- 3XLN, 143 Ruff Tex, 415-N, Food King 1W